Resurfacing your synthetic sports pitch can be a daunting task. It’s a significant investment every 8 to 12 years which also offers a brilliant opportunity to upgrade your facility to meet the demands of today’s participants and community. However, without the right information from the start, the project can throw all sorts of curveballs your way.

To support pitch operators with this process, Blakedown Sport & Play have developed the following factors to help ensure all elements are considered:

1. When do sport pitches need resurfacing?

Synthetic pitches generally require resurfacing every 8 to 12 years, depending on the original quality of the installation, the product, usage, and the level of maintenance over this period.

Key signs to look out for include yarn worn down or flattened, uneven surfaces, bald spots, compactment, poor drainage, tears, seams coming apart and a buildup of mold or vegetation that is hard to remove, making the surface slippery.

Depending on the severity of these signs, it may be possible to extend the life of your pitch by completing a higher level of maintenance, patch repairs, or rejuvenation that may give you another 0-2 years before requiring a full resurface.

2. Pitch surface design

Once you have concluded that a resurface is required, this is a good opportunity to review your facility and ensure it’s suitable for your user groups over the next 10 years.

Start by determining the demand in your area to establish your priority sports. The surface you select will then be based on these priority sports. Please note, there is not one perfect surface suitable for all sports. It’s important to understand this before making a decision on the surface type.

Consider the level of surface required. For example, there is a significant difference between an FIH category 1 international level water-based hockey surface and a FIH category 4 multi-sport surface suitable for community use.

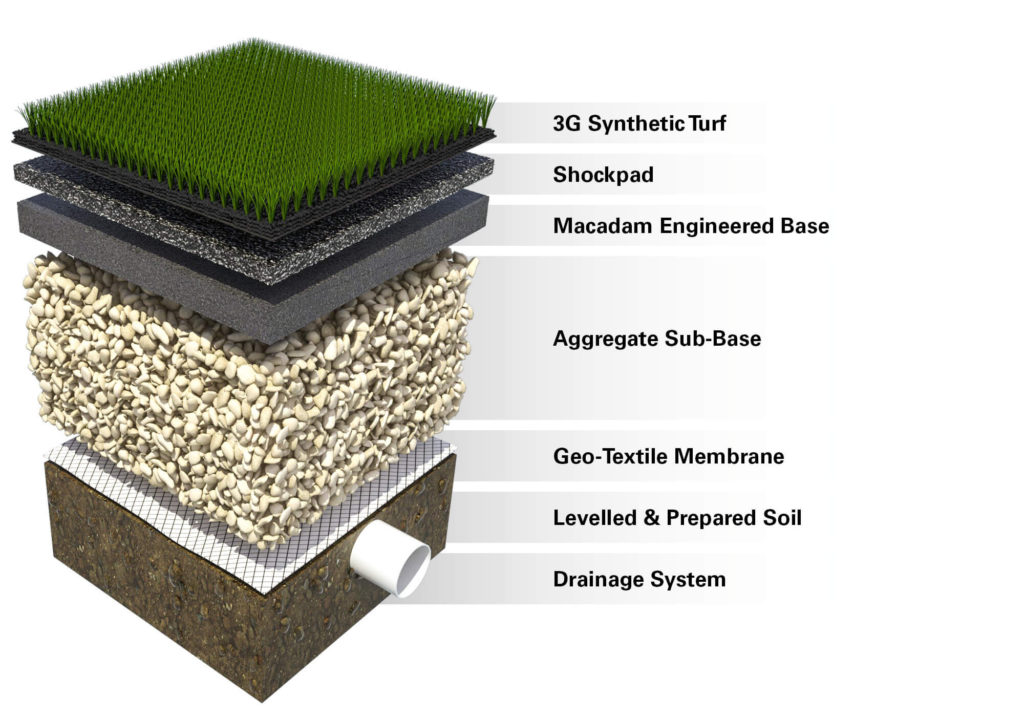

Also, consider what is underneath your surface. While the top surface/carpet of a facility lasts 8 to 12 years, some surfaces will require a shock pad underneath, which could last 20 years and may also require replacing. The base under your shock pad also needs consideration—generally, there are two types: “dynamic” and “engineered.” The dynamic base offers initial cost savings but can bring risks later on. Addressing this during a resurfacing project can help avoid future risks.

While your pitch is being resurfaced, it’s also a good opportunity to review ancillary works, such as fencing, gate positioning, floodlight upgrades to LEDs, spectator area locations, and whether you need to consider an extension on your facility or line marking to section it up further to maximise income from smaller bookings.

3. Environmental factors

While a synthetic pitch is ultimately a field of plastic, it doesn’t have to harm the environment. There are now options to ensure your old synthetic surface is fully recycled into other products sold on the market. There are organic or biodegradable infills for 3G pitches to avoid the use of SBR (rubber crumb). There are also a full range of micro-plastic retention measures for SBR infills, and surfaces made from “turf to turf” technology, meaning your new surface will be made from 50% of an old pitch, and 100% of your surface at the end of its life will go back into a new pitch – closing the loop.

4. Pitch management and maintenance

Resurfacing and upgrading your facility also gives you an opportunity to review how your facility will be managed and maintained for the next 10 years.

It’s essential to have a good maintenance program in place to maximise the life of your new facility, which can be a balance of professional contractors and internal teams depending on your resources. Managing your new facility is equally important to meet rising demands on-site and compete against other facilities in your area.

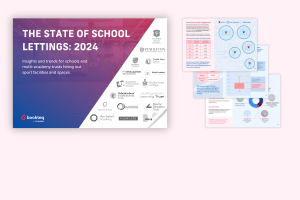

5. Funding and sustainability

At this stage of the process, you maybe now have a good idea of the project’s price, leading you to review funding options. Funding for synthetic pitch projects can come from various sources: in-house investment, private investment, section 106 funding, Football Foundation, Sports England small grants, or local charity pots specific to your area. Partnering with other local groups or clubs is also a good option, as synthetic facilities are generally in high demand for numerous sports clubs.

Sink funds are also not to be overlooked and it’s a good idea to consider these when completing your business plans. This is the amount set aside to help resurface your facility again in 10 years’ time. This price will vary based on your current facility’s condition and the surface/shock pad option you choose.

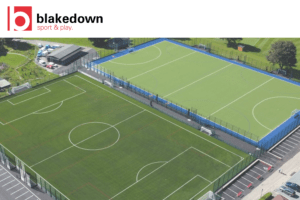

Free consultation available by Blakedown Sport & Play

Blakedown Sport & Play is one of the largest and longest-established sports construction contractors in the UK. Their services include supplying organisations with the design, construction, resurfacing, and maintenance of sports facilities. As a SAPCA-approved principal contractor and an FIH-certified field builder, they deliver many projects each year, ensuring all constructions meet industry guidelines and standards. Most projects are officially certified to the standards set by FIFA, World Rugby, FIH, and World Athletics, ensuring the highest quality and performance.

If you would like support with any of the above information, please get in touch with Blakedown now for a free consultation.